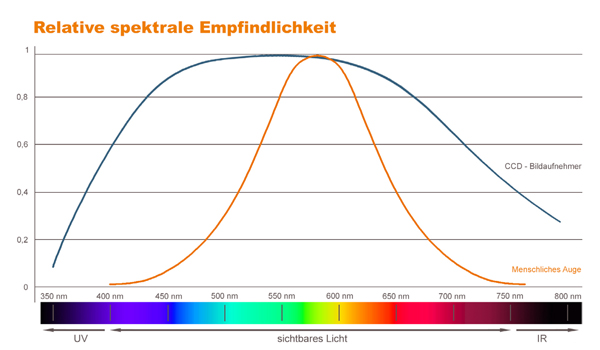

Resolving capacity: Short-wave and long-wave light in industrial image processing

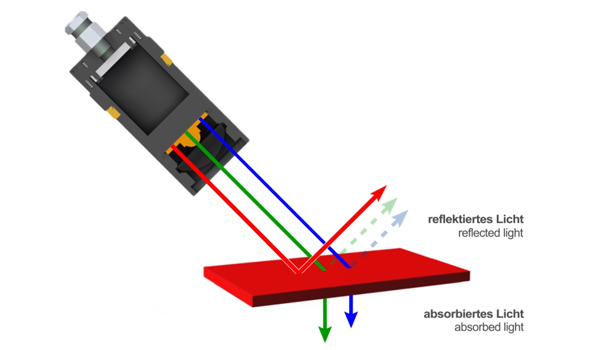

The last few sections in this chapter have looked at the interactions of light with coloured objects. Yet the decision for or against a certain wavelength is not only of interest in the context of coloured test objects. For both reflected light and backlight systems, the choice of the right wavelength has a decisive role to play.

Reflected light

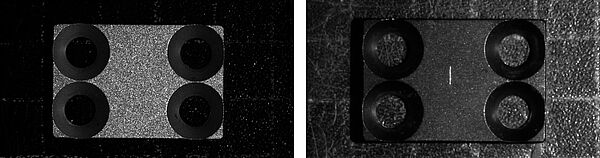

When inspecting surfaces for features, damage and soiling – such as embossing, scratches or dust, for example – the use of shortwave light is recommended. This is reflected more strongly than longwave radiation, and can be used to make even minor irregularities clearly visible. Under longwave light, however, which penetrates more deeply into the material layers, these small surface defects are barely visible. The difference in contrast is minimal, which means that analysis using a Machine Vision system can not be implemented. One portion of the longwave light is reflected directly at the surface. The other portion is transmitted by the object surface and this is irradiated back only by deeper layers within the material. Reflection is more diffuse in comparison to shortwave light, which reflects directly on the material surface. In the test object image, object edges therefore appear comparatively less sharp. Effects increase proportionally as the wavelength of the radiation used becomes shorter or longer. For this reason, intensely blue or ultraviolet light is used for surface inspection work.

Source: en.wikipedia.org

Nor should the effects of various wavelengths be overlooked for backlight systems. The primary concern here is light diffraction. Put simply, the diffraction effect is the propagation of light behind an edge. When light travelling as a wave hits an object, it will be deflected. Behind an object edge, the waves of light spread out in all directions and overlap one another. Diffraction will be more pronounced with longwave light. This is especially important for the imaging of objects and their edges, and taking measurements in backlight systems. If shortwave light is used instead, object edges will be imaged more sharply and with richer contrast, as shortwave light diffracts less strongly around the object. This minimizes edge washout in the image while increasing Machine Vision measurement accuracy.