Strobe lighting vs. continuous and switching lighting: suppress extraneous light and avoid motion blur

Continuous and switch operation

When working with continuous lighting, the light source is operated permanently with nominal current. Accordingly, it is not necessary to switch the lighting system on before recording an image. This mode is needed for rapid processes, for example, where the image acquisition frequency is much higher than the pulse/flash frequency that the lighting is capable of. As a result, this operating mode is often used for line-scan camera applications. In addition, many inexpensive lighting solutions have no switch inputs, so they can in fact only be operated in continuous operation.

Pulse or switched lighting solutions are also operated with nominal current, and therefore provide the same level of brightness as continuous lighting. Using fast, opto-isolated PLC and TTL switch inputs, however, these lighting systems can be switched on at the moment of image acquisition and switched off after the image is taken. The primary advantage to using switch operation is extending the service life of the LEDs: shortening the LED duty cycle can decisively lengthen the useful life of these parts. Compared to a continuous lighting system, a system operated for only half of the power-on time can achieve a service life that is twice as long.

Pulse or switch operation is itself often confused with strobe operation. In strobe operation, however, the LEDs are powered on for an extremely short period of time but at a much higher level of light output. This can solve problems that arise due to extraneous light or motion blur.

Strobe lighting

Any hobbyist photographer will be familiar with the use of a flash. But flash is not only a useful form of lighting for SLRs, digital cameras or phone cameras. Particularly in an industrial context, flash is a topic that is rapidly growing in popularity.

For industrial Machine Vision applications, however, flash units and integrated camera flash lighting is not used. Instead, the forms of lighting used are exactly those discussed in chapter 1. These lighting systems are equipped with a specialised – and typically integrated – strobe controller capable of ‘flashing’ the system’s LEDs rapidly, precisely and with high-intensity output. When flashed, the LEDs are operated at a very high current. In this way, the brightness can be increased by a factor of up to 25 compared to continuous and pulsed lighting. Nor is strobe lighting merely orders of magnitude brighter: when the trigger signal is sent, the maximum light output of the lighting system is available within a period of time measurable in single-digit microseconds. This fast availability in conjunction with the enormous light output triggered means a very short exposure time can be set on the camera. The exposure time is therefore set to the flash duration and lies between 10 and 750 µs.

Thanks to the extremely short exposure time, the following problematic effects can be minimised:

1. Motion blur

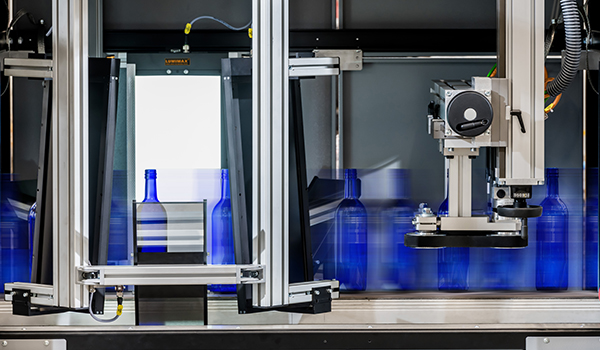

The use of robots or conveyor belts to improve both productivity and throughput times always means one thing: accelerating motion within the process. Nor should the Machine Vision system act as a brake on this process speed. To ensure this doesn’t happen, the best approach is to acquire and analyse the image without interrupting the process. But can you guess the maximum exposure time possible if your object is moving at 0.5 m/s and you must also ensure that image blur does not exceed 2 pixels? Exactly 100 µs.

This would be inconceivable with continuous or pulsed lighting: their luminous intensity is simply too low to light the object properly. The switch-on delay for pulsed lighting is also much too long.

With strobe lighting, however, the maximum light output is available within 5 µs and a vast amount of light is provided. As has been mentioned above, very short exposure times are therefore not a problem at all. The moving object can simply be ‘frozen’ in place (see video below). For the human eye – and the camera – the moving object seems to come to a complete stop, and image analysis is now simple to perform.

2. Extraneous light

With short exposure times and the very high luminous intensity supplied by flash lighting, extraneous light can also be completely suppressed. With an exposure time of no more than 750 µs, even light from a window located right next to the camera or other light source will not be picked up and will therefore have no effect on the final test object image. This hugely increases the reliability of the analysis. In large, spacious factory buildings in particular, this means not having to worry about environmental conditions or ambient light disrupting camera-based inspection systems.

3. Stray light

Interestingly, the human eye perceives flash lighting as less distracting than pulse lighting. While this may not seem entirely logical at first glance, take a look at the following video:

In the lower image, the strobe lighting seems significantly darker than the pulse lighting. Even though the flash is actually much brighter – as can be seen on the camera image in the video. The effect stems from the fact that our eyes cannot see the short, rapid light flashes at their full intensity. Accordingly, the lighting is perceived as less distracting.