Polarisation filter: Suppress light reflections on shiny and reflective test objects

When working with light, distracting reflections in the camera image – caused by lubricants, foils, paints or simply by reflections from glossy or mirror-like surfaces – are a recurrent problem. These distracting effects can be suppressed by the use of polarisation filters.

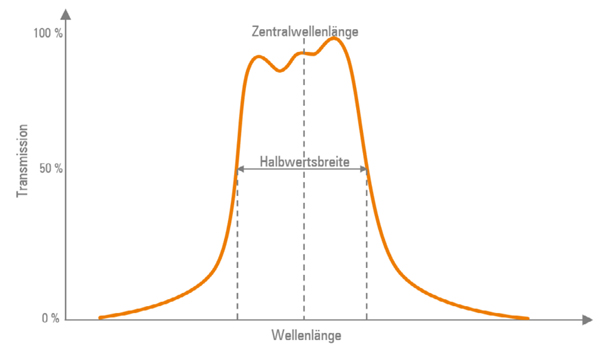

Polarisation describes the process by which light is restricted to a single direction of oscillation. Various options are available for achieving polarisation to improve an image within Machine Vision systems.

Polarisation by using polarisation filters

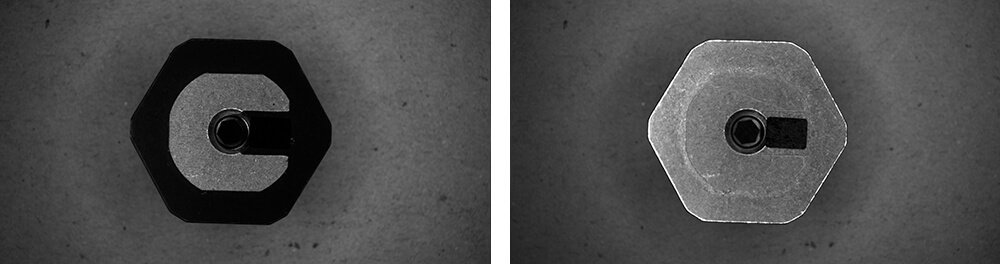

In industrial Machine Vision, systems usually work with two linear polarisation filters. One is located in front of the light source and a second in front of the lens. The light emitted by the lighting can oscillate in all directions. The polarising filter in front of the lighting transmits light in just one oscillation direction, however. Light rays with other oscillation directions cannot pass through the filter. If another filter is now placed in front of the lens, then the polarised light can either be allowed to pass or attenuated, as required.

Polarised light is especially useful for suppressing distracting reflections. At the opposite end of the system – the lens – a second polarisation filter is set up as an attenuating filter. This acts to minimise reflections, and the camera image lighting is significantly more homogeneous. Since this kind of setup results in a lot of light being lost, however, working with especially powerful lighting systems – such as High Power Lighting – is strongly recommended.

Another approach involves exploiting the surface properties of various types of objects. As just one example, this can be used to make transparent films such as adhesive pads or labels visible on metallic backgrounds. While the metallic background reflects the polarised light back into the camera, the film changes the direction of polarisation for the incident light. Accordingly, if the polarised light is blocked at the camera, only the film remains bright and can therefore be easily detected.

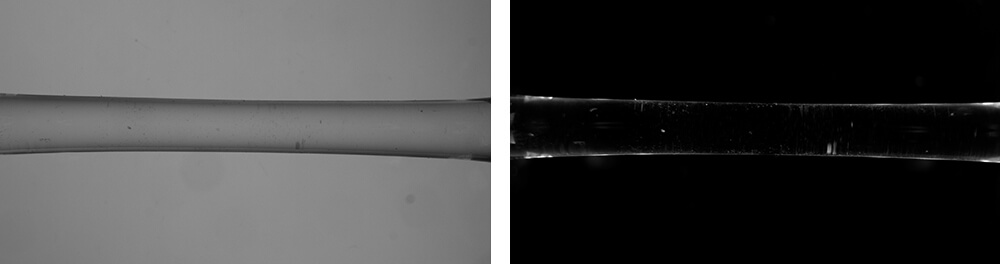

Polarised lighting is not only suited to reflected light. With a polarised backlight system, even transparent plastics and glass can be made visible. If the lens filter is configured as an attenuating filter, a dark image is first obtained. If a transparent object is present in the image, however, then this changes the oscillation direction of the light and it appears bright before the dark background. Even the arrangement of stress fractures in the objects can be identified, since these change the oscillation direction yet again.

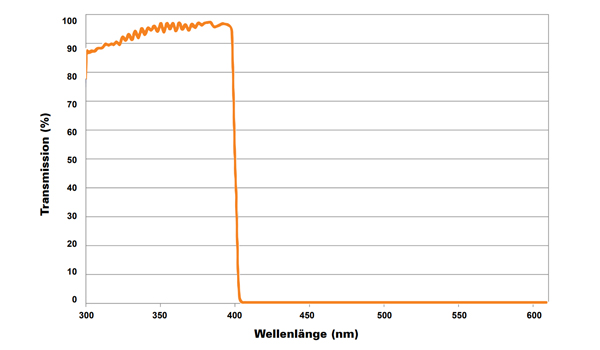

Polarisation by the surface

If the polarisation angle – or Brewster’s angle – is taken into account, then the surface of the test object itself can actually be used to polarise the light emitted by the lighting system. If the light falls onto a non-metallic surface at this particular angle, then the reflected portion of the light will be polarised parallel to the surface. If a polarisation filter has been set up as an attenuating filter in front of the lens – i.e. rotated 90° – this can suppress distracting surface reflections.