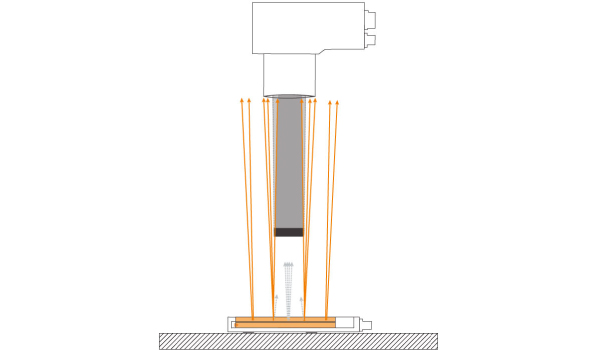

Diffuse backlight in machine vision applications

With this form of lighting, a diffuse light source is positioned behind the object. Unlike reflected-light lighting, this means the contours of the object are lit instead of the object itself. A “shadow image” is the result. In the shadow image created, the object’s outline and (open) inside contours are readily visible. The object appears as a black area in front of a white background. The high level of contrast achieved hugely simplifies the subsequent image analysis.

Diffuse backlight lighting is primarily used in the following applications:

- Contour inspection

- Presence inspection

- Machined hole inspection

- Orientation/rotary orientation inspection

- Residual soiling analysis

In addition, diffuse backlight lighting is also useful for the imaging of transparent and semi-transparent objects. This can be used to check the fill levels of bottles and jars during filling, for example. With longwave light, this approach even works with transparent liquids such as water. Diffuse backlight lighting is also well-suited to applications requiring the high-contrast imaging of defects or features in diaphanous glass or plastics.

Both scratches in glass and features such as embossing or grinding can be imaged using this form of backlighting. With the help of polarisation filters, the current range of possible applications now even includes testing glass for stress fractures.