Bright field illumination is a form of incident light illumination. Imagine the object plane as a flat mirror. If the lighting is aligned so that the light is reflected directly back into the camera, this is referred to as a bright field arrangement.

This makes this type of light control particularly suitable for:

- Surface inspection

- Display of embossed, needled and lasered characters and code

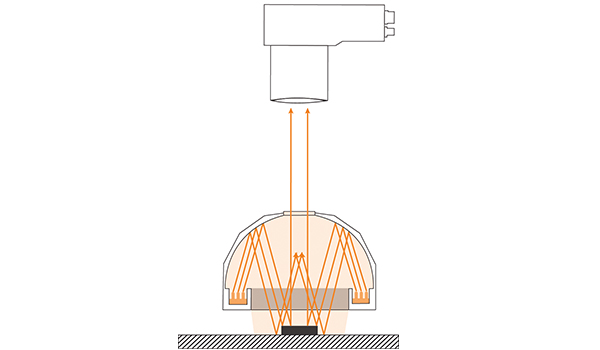

A bright field can be achieved with coaxial mirrored illumination, for example. With this form of illumination, a diffuse, homogeneous light source is introduced directly into the beam path of the optics via a semi-transparent mirror. As a result, the object is illuminated very evenly and without shadows. The vertically incident light is reflected from the flat surface directly back into the camera. Unevenness in the surface, on the other hand, deflects the light and appears dark.

This lighting is recommended for illuminating highly reflective and mirrored surfaces. However, 50% of the light is lost each time it passes through the mirror. This means that only 25% of the emitted light reaches the camera. In order to still obtain a well-lit, high-contrast image, coaxial mirrored lighting is used with a small working distance.

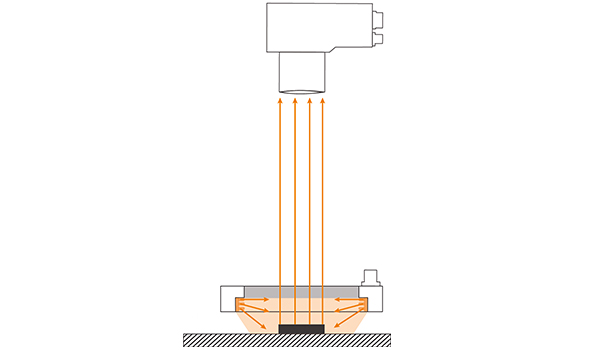

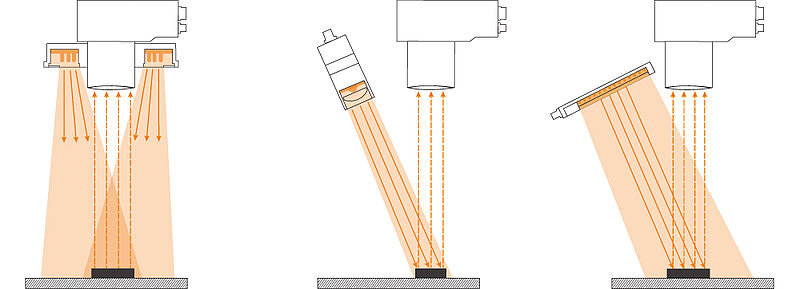

An alternative bright field arrangement, which is also suitable for larger working distances as well as matt and rough surfaces, is based on the law of reflection already explained:

Angle of incidence of the light α = angle of reflection of the light β

If the lighting is positioned at a certain angle to the object plane, the camera must be tilted at the same angle - but in the opposite direction to the perpendicular line. In this way, the light rays are reflected from the flat surface directly into the camera.

As with coaxial reflected lighting, the light rays are deflected by unevenness, causing them to appear dark on the otherwise bright background.

Partial bright field lighting

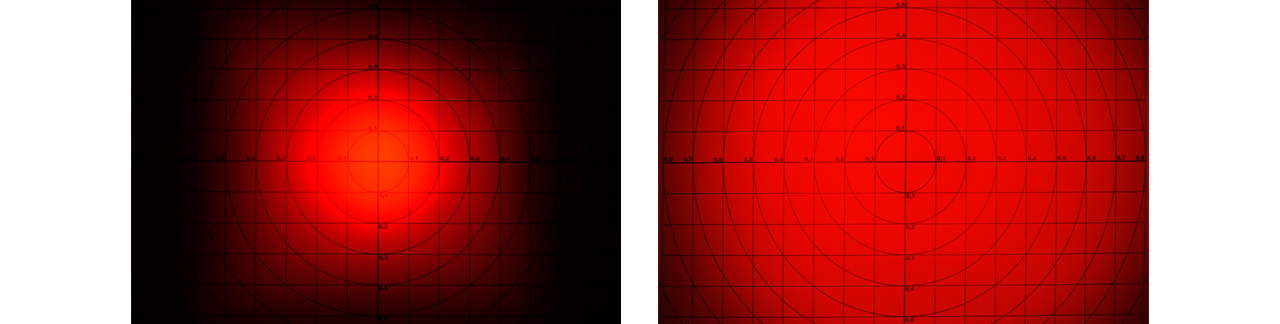

The partial bright field arrangement is the most commonly used illumination technique. In contrast to the bright field arrangement described above, the angle of incidence and angle of reflection are less important with this lighting technique. The light shines onto the test piece from the direction of the camera using ring lighting or at a slight angle with spot and area lighting:

Highlighting surface defects, edges and unevenness is not the aim of this type of lighting. Rather, the aim is to illuminate the entire image field as homogeneously and brightly as possible. This makes the partial bright field particularly suitable for uniform illumination of rough and matt objects.

Typical tasks for a partial bright field are:

- Identification of placement, type and position

- Print inspection

- OCR / OCV

A wide range of lighting accessories, such as diffuser discs, polarization filters and Fresnel lenses, allow the lighting to be adapted to a wide variety of tasks and ambient conditions.

Thanks to the option of changing the lenses or complete lens arrays in front of the LEDs, LUMIMAX® High Power LED lighting can be flexibly adapted to a wide range of requirements. For example, objects can be illuminated from a distance of several meters using lighting with a narrow beam angle. A wide beam angle, on the other hand, ensures homogeneous illumination and powerful illumination of large objects even from shorter distances.